Challenges related to the water required for renewable H2 production

In recent years, due to climate change, the number of droughts is increasing worldwide. In Spain they are becoming more and more common, especially in the Mediterranean areas. We can highlight Catalonia, for example, a region that in recent months has been suffering from a depletion of its water reserves. This means a shortage of one of the most important resources on Earth, fresh water, which is a fundamental part of countless processes worldwide, from livestock farming to energy generation.

More specifically, the renewable hydrogen generation sector requires a continuous supply of water. Primarily, water is necessary because it is one of the raw materials for producing so-called renewable hydrogen, provided that the electrolyser is powered by renewable energy. Secondly, water is needed for cooling the heat produced.

Water in the production of hydrogen

There are currently different hydrogen production technologies, although for this analysis we will divide them into non-renewable hydrogen, colloquially known as gray hydrogen, non-renewable hydrogen with carbon capture (blue hydrogen) and renewable hydrogen (green hydrogen).

Although the use of water in hydrogen production is still in the early stages of research, different approximate water consumptions are known for different technologies:

- The water requirement for renewable hydrogen production technologies is 17.5 liters per kilogram of hydrogen produced for PEM technology, 22.3 L/kg for alkaline technology and 10.8 L/kg for SOEL technology.

- For non-renewable hydrogen production technologies using steam reforming, water consumption is 17.5 L/kg, and for hydrogen produced by coal gasification, 31 L/kg is required.

- Non-renewable hydrogen with carbon capture requires 32.1 L/kg for production and carbon capture by reforming and 50 L/kg for production and carbon capture from coal gasification.

In 2021, it was estimated that 86 Mt of hydrogen were produced worldwide, where the vast majority of this was non-renewable hydrogen. In the coming years, hydrogen production will grow considerably worldwide, estimated at 247 Mt by 2040, where 166 Mt will be renewable and 81 non-renewable with carbon capture, and at 523 Mt by 2050, with 94 % expected to be renewable.

Logically, this worldwide increase in hydrogen production implies the need for a greater supply of water to meet these estimates. This will increase from the 2.2 billion m3 consumed today, or 0.6 % of the water consumed in the energy sector, to 7.3 billion m3 by 2040 and 12.1 billion m3 by 2050.

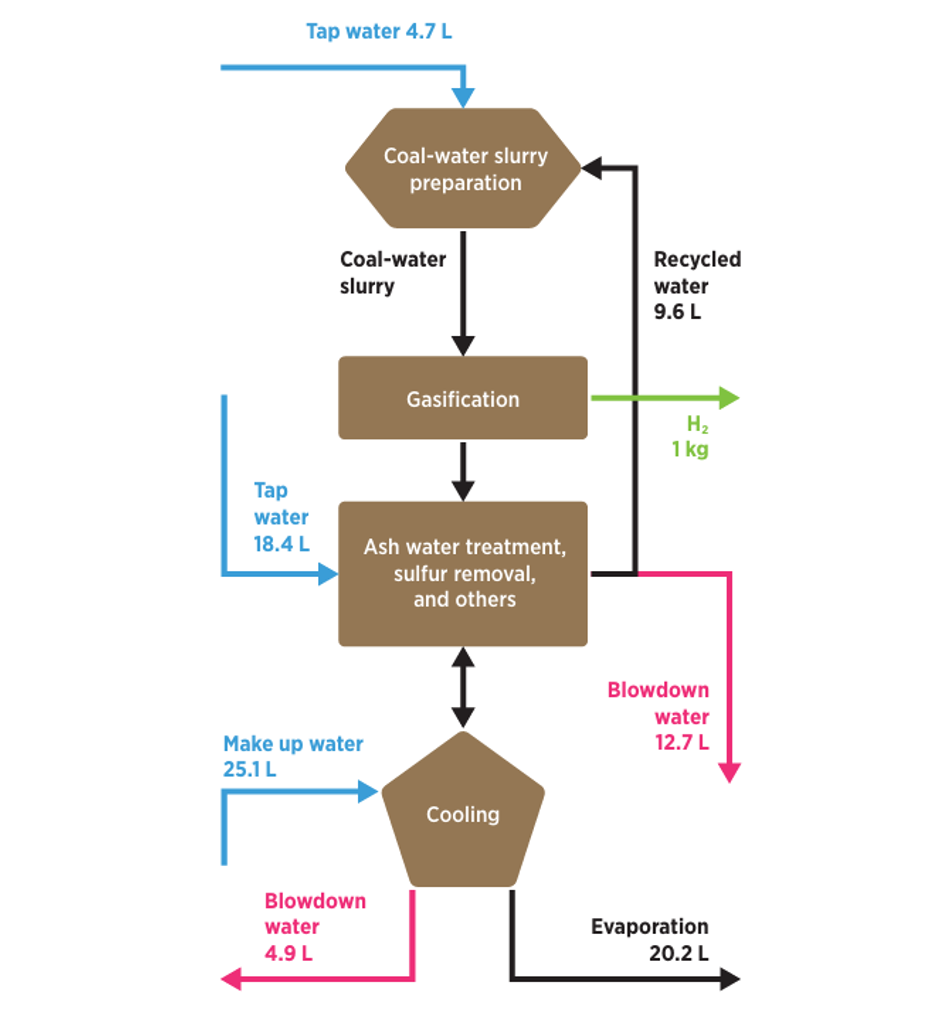

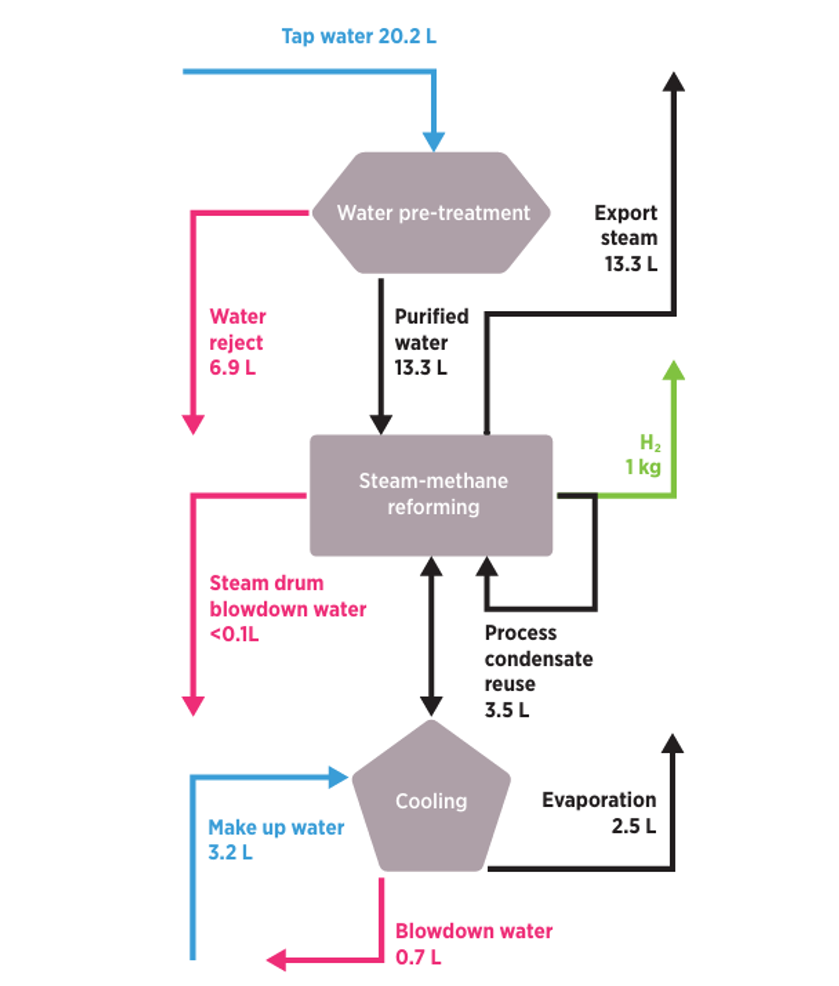

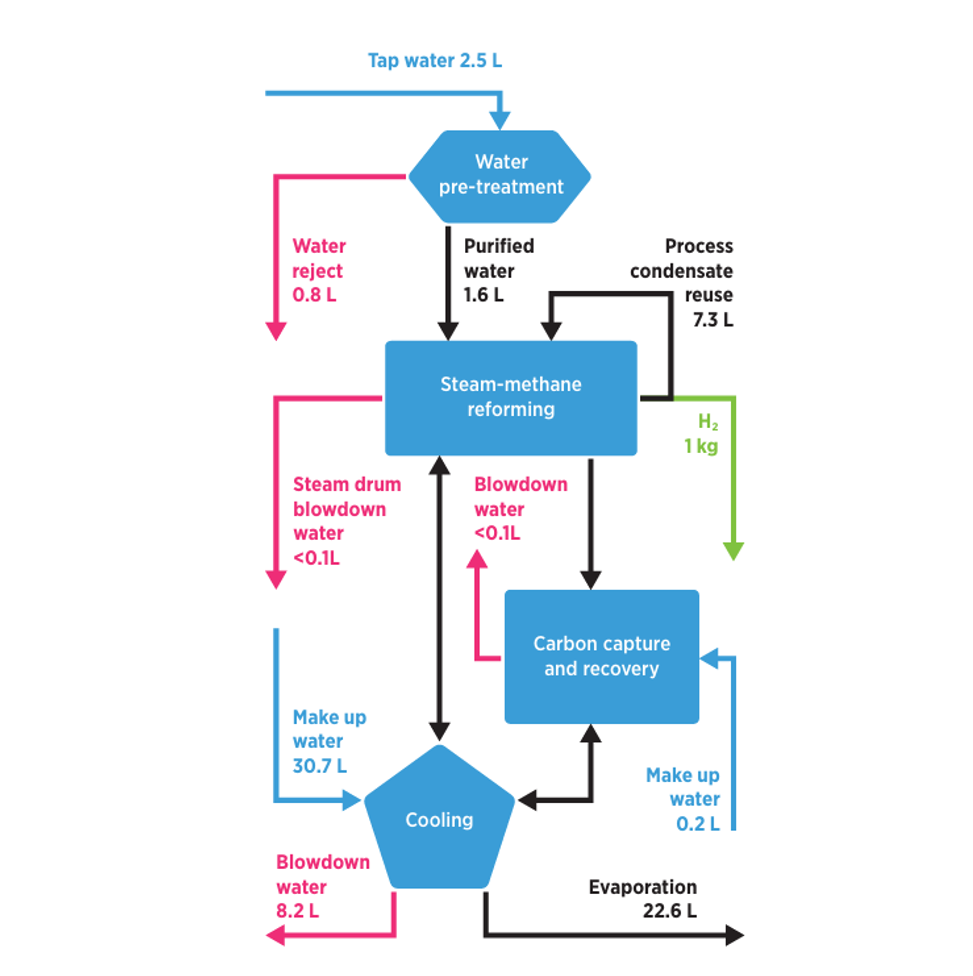

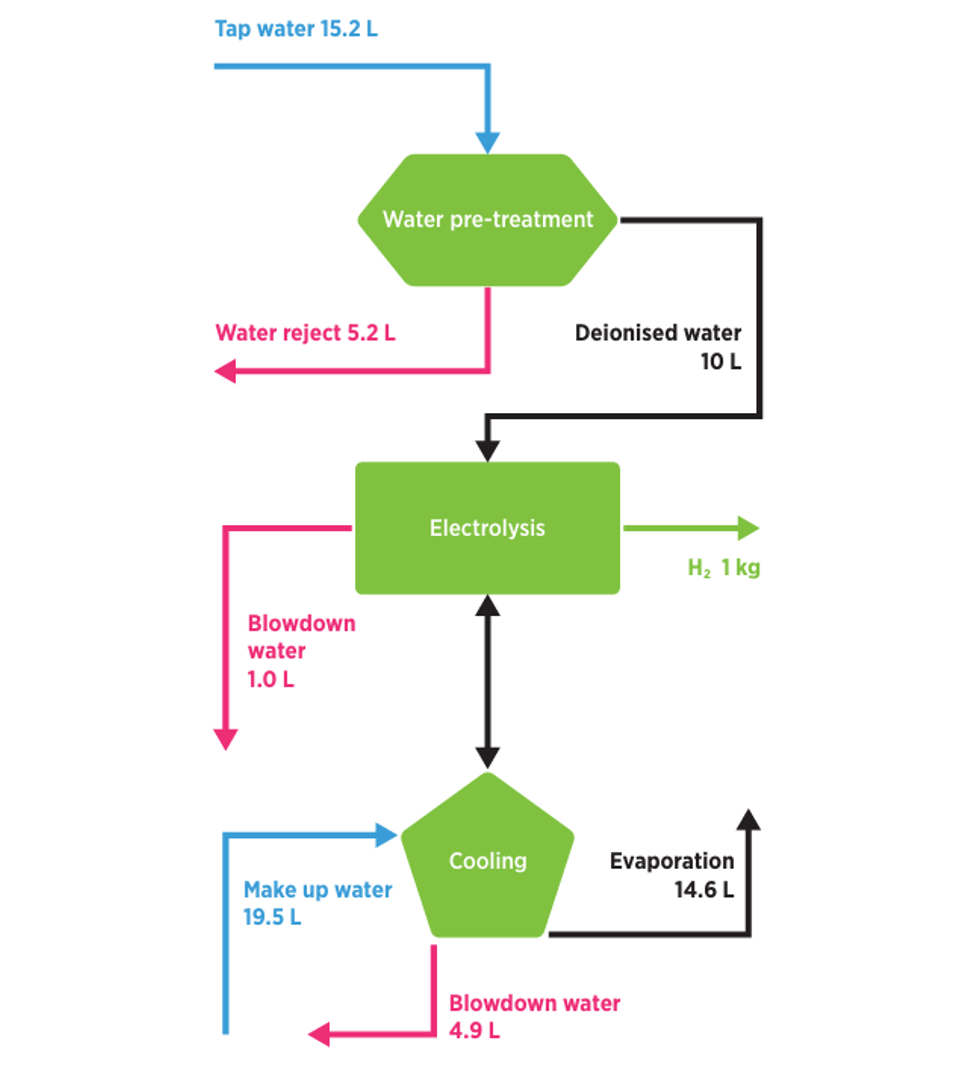

The supply diagram for the different types of hydrogen production technology is as follows:

- Hydrogen production technologies based on coal gasification have water consumptions of 26.1 L if from groundwater or rivers and 43.5 L if from salt water, where water consumption related to carbon capture is not considered.

Figure 1. Water consumption scheme in hydrogen production by coal gasification

- Hydrogen production technologies based on methane steam reforming have water consumptions of 22.9 L if it comes from groundwater or rivers and 38 L if it comes from salt water.

Figure 2. Water consumption scheme in hydrogen production by methane steam reforming

- For technologies with carbon capture, there is an extra supply of 2.8 L if the water is obtained from rivers or groundwater and 4.7 L if seawater is used. In addition to these quantities, there is the aforementioned consumption of 32.1 L/kg for reforming and 50 L/kg for coal gasification.

Figure 3. Diagram of water consumption in hydrogen production by carbon sequestration

- Hydrogen production technologies based on electrolysis have an average water consumption of 17.2 L if it comes from groundwater or rivers and 28.6 L if it comes from salt water.

Figure 4. Diagram of water consumption in hydrogen production by means of electrolysis

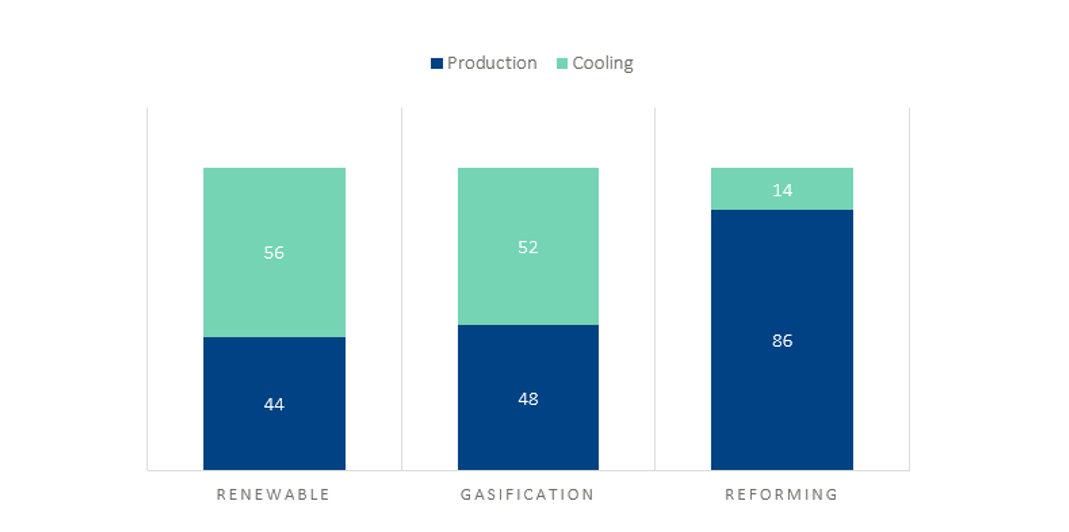

Due to their technical characteristics, each type requires a different water supply; for non-renewable hydrogen production, 14 % of the supply is used for cooling, for hydrogen with capture, 92 %, and finally, for renewable hydrogen, 56 % of the total supply is used. The cooling of the different systems is carried out in closed loops, so that no water is consumed except for possible losses due to evaporation and leaks that may occur in the circuit.

Figure 5. Use of Water in Hydrogen Production Technologies

Water withdrawal for cooling is 29% currently, although the transition from steam-reformed (with cooling) to green and blue hydrogen (with a high cooling requirement due to carbon capture), may increase to 62% by 2040. However, since green hydrogen is expected to account for the vast amount of production by 2050, the share of refrigeration in the global hydrogen production market could decrease to 46%.

The geographic problem of water consumption

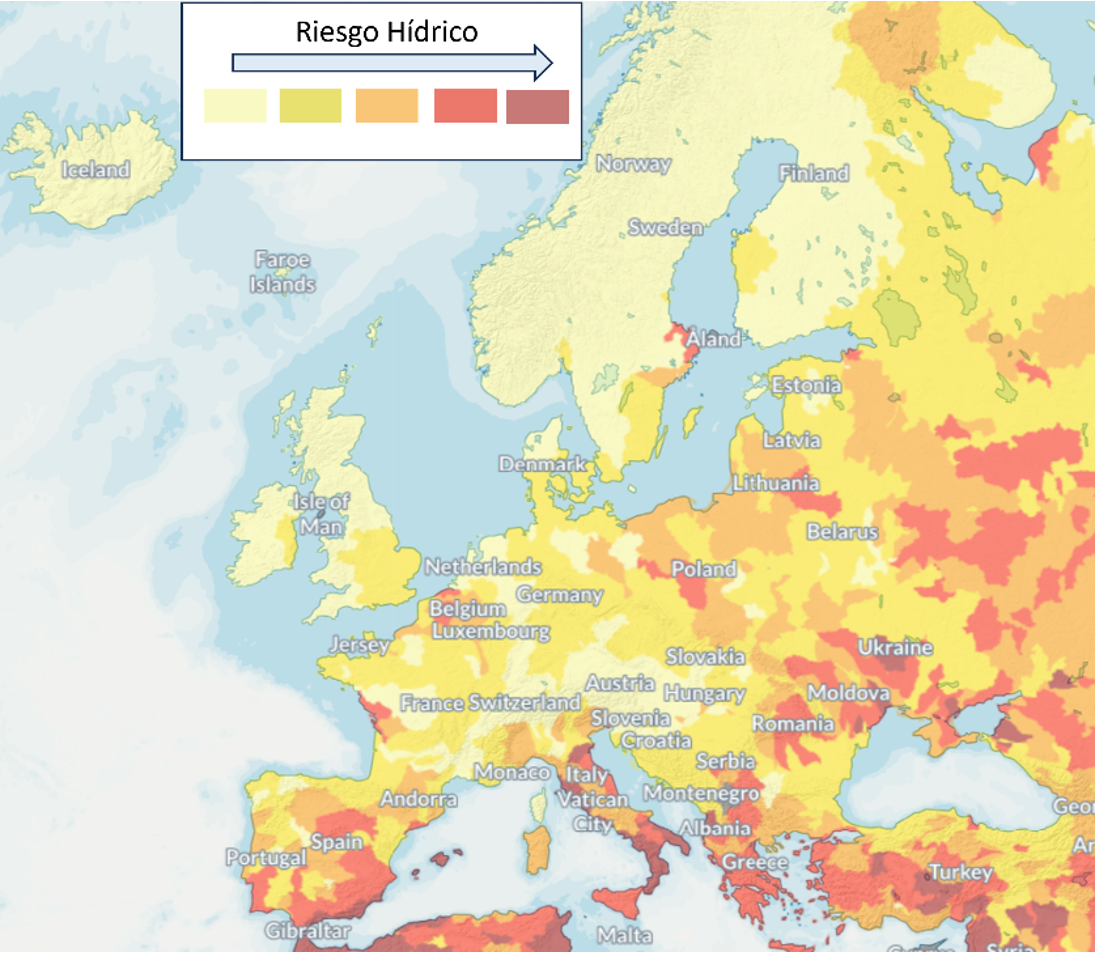

Europe faces several challenges in the coming years with respect to increasingly frequent droughts, which will have an impact on electricity generation and, in particular, on the production of electrolytic renewable hydrogen. Of the large number of projects planned on the European continent for hydrogen production by 2040, 37% will be in areas with high water stress. Although water consumed for hydrogen production does not have a significant impact globally, it can have a detrimental impact locally in situations where water reserves are not abundant.

According to Water Risk Atlas (Aqueduct Water Risk Atlas (wri.org)) the current water risk situation in Europe is as follows:

Figure 6. Water stress in Europe

Where the Mediterranean basin stands out as the most stressed areas at present. These are the areas where most of the hydrogen production projects will be implemented due to their great photovoltaic potential, although they are linked to a large number of droughts suffered in the continent.

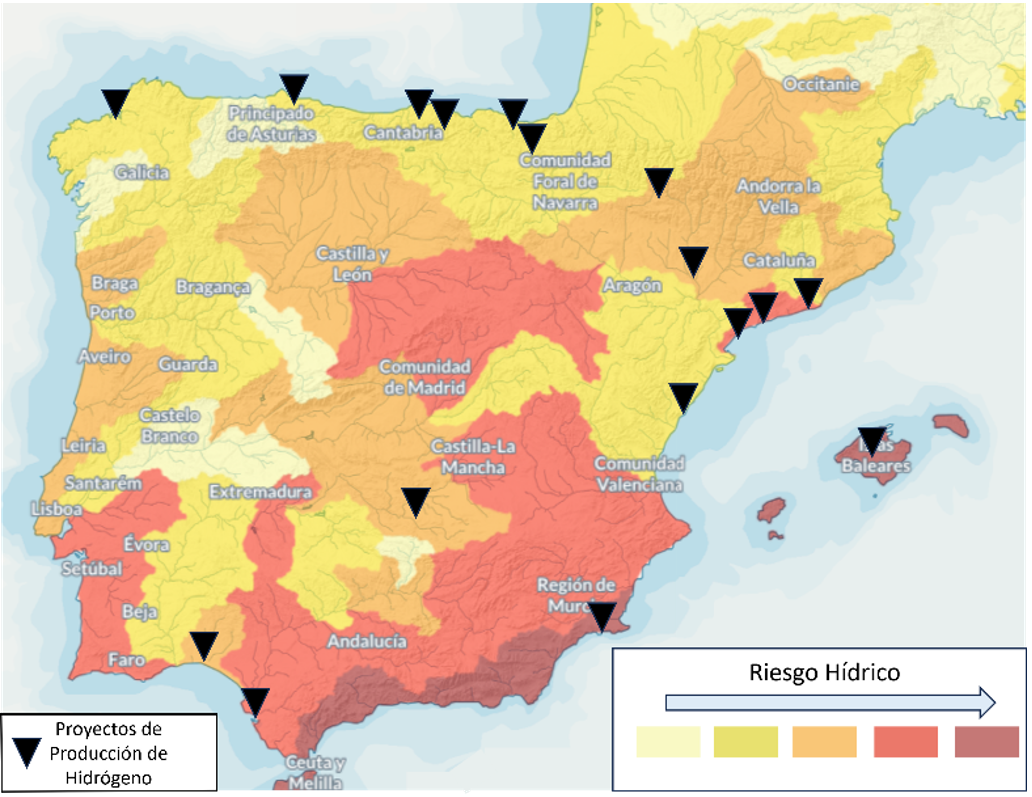

At a national level, the same problem is found as in the rest of Europe, the greatest water stress is in the coastal areas of the Mediterranean, where many electrolytic hydrogen production projects are intended to be carried out. The water risk forecast for the coming years is shown below.

In the rest of Europe, 64 % of the total number of hydrogen production projects already under development in the national territory are in areas with water risk, and in 2050 most of them will be facing water shortage. It is therefore necessary to implement saltwater treatment plants to supply the electrolysers.

Figure 7. Implementation of hydrogen production plants in Spain

Solutions to water problems

As mentioned, in the coming years there will be an increase in droughts as a result of climate change. This will pose problems not only for the renewable hydrogen value chain, but also for the rest of the industrial and non-industrial sectors, such as agriculture and livestock. There have already been problems in the French power generation industry, where drought and rising temperatures have made it impossible to cool part of its nuclear power plants.

Therefore, governments should control the implementation of renewable hydrogen production projects in water-risk areas. They can also set aside incentives for hydrogen production technologies that require less water supply, such as those generated by renewable electrolysis. Although it is not the technology with the lowest water supply requirements, it is the only one that does not emit GHGs, and does not require carbon capture, which entails higher water consumption.

R&D projects that seek to increase the efficiency of electrolysers should be promoted, since for each point of increase in equipment performance, heat extraction is reduced and water consumption is reduced by 2%, which for industrial power decreases the water supply.

The more energy efficient the electrolyser is, the less waste heat will be generated and will have to be evacuated, and less water will be needed to cool the system. The lines of research for improvement in this aspect are focused on:

- Improvements in the resistance of membranes in ionic transport.

- Improvements in the evacuation of the gas bubbles formed that hinder the electrochemical reaction.

- Improved catalysts at the anode and cathode.

Research is also needed on water treatment processes since water quality is a key factor in hydrogen production. And current desalination techniques must be improved to obtain more water and less energy. R&D efforts should also be focused on the development of electrolysis technologies that require less pure water, and even allow operation with “salt” water.

Conclusions

Hydrogen projects consume significant volumes of water, which could be of concern for water-scarce regions. The hydrogen industry’s water demand is only a fraction of that of the energy sector and is likely to remain so for the next two to three years. For these reasons it is important to favor the industrial-scale development of hydrogen production solutions with a lower water use requirement, which as previously mentioned are electrolytic technology solutions.

As most of the hydrogen production projects will be carried out in coastal areas with abundant hours of sunshine per year, it would be interesting to use desalinated water, if possible from renewable energies. However, as the processes responsible for removing the salt from the water are electricity-intensive, the use of these desalination plants must be properly managed, as they decrease the overall yield of hydrogen production. In addition, the saline residues from the implementation of such plants, which have a non-negligible environmental impact, must be managed.

The geographical planning of the implementation of future renewable hydrogen production projects in the European Union will be a factor to take into account. It will be necessary to consider the renewable potential of the area in which the hydrogen production facility will be developed, and the possible water stress that the area may present when the project is initiated and the forecast that the site may present in the coming years.

It is necessary to comment that hydrogen production for the year 2050, in which the objectives proposed by the European Union will have been achieved, the amount of water required will represent a small percentage compared to other sectors. In Spain, for example, 80% of water is used for agriculture. Similarly, as has been seen in recent years in regions of the national territory, such as Catalonia, there is a deficient water supply infrastructure, resulting in large losses due to lack of proper maintenance. The development of this type of infrastructure throughout the country can be a total compensation for the additional water consumption generated by hydrogen production.

Finally, reference should be made to the improvement in the energy efficiency of electrolysers. At electrolyser scales of more than 100 megawatts, a percentage increase in electrolysis efficiency will lead to an exponential reduction in the water required for production and cooling.

REFERENCES