Hydrogen and heavy transport: IAA Transportation 2022 Hannover (Part Two)

In the first blog of the IAA Transportation Hannover 2022, we summarised the latest innovations of the leading manufacturers of heavy-duty vehicles regarding hydrogen propulsion, whether in its compressed gaseous or liquid state, as well as the different technological and component mobility solutions of the leading hydrogen suppliers.

In this second report, we will focus on trucks and buses powered by hydrogen ICE internal combustion engines as well as new developments in retrofitting and modifying chassis for hydrogen technologies. We will also analyse manufacturers that are committed to hydrogen range extenders and the latest powertrain components from some technology suppliers. Lastly, we will mention the “made in Spain” products at the exhibition, specifically the digital diagnosis and predictive maintenance solutions from the Cojali Group from Castilla-La Mancha.

MAJOR DEVELOPMENTS FROM ICE HYDROGEN-POWERED VEHICLE MANUFACTURERS

Cummins & Westport Fuel Systems

The North American manufacturer dedicated to designing, manufacturing, distributing, engineering and servicing solutions for diesel engines and different fuel systems, including hydrogen, unveiled the B6.7 Hydrogen ICE internal combustion engine at the IAA Transportation in Hannover this year. Cummins unveiled a truck equipped with a hydrogen-powered ICE engine. For this purpose, the company replaced the diesel engine of a Mercedes Benz Atego 4×2 truck with a 6.7-litre hydrogen engine (B6.7H) with a torque of 1,200 Nm and an electrical output of 216 kW. The company could prove that there was no loss of performance or payload in a range of 10-26 t payload trucks.

The Canadian company Westport Fuel Systems also launched a truck with a hydrogen combustion engine and not only reported no losses, but also a 20 percent increase in performance over a conventional diesel engine. Torque has also increased by 18 percent.

KEYOU

The German company founded in 2015 that is specialised in hydrogen ICE combustion engines showed for the first time its two solutions for heavy cargo and passenger transport. More specifically, a 12-metre city bus and an 18-tonne truck were unveiled. Both prototypes are based on the 7.8-litre hydrogen engine developed by KEYOU. The 18-tonne truck is designed on a Daimler Actros chassis and the assembly work has been performed by Paul Nutzfahrzeuge GmbH, the European leader among special-purpose vehicle manufacturers, which will be explained later in this report. Less than 11 kg/100 km fuel consumption for city buses and 7 kg for low tonnage trucks as well as the large reduction in NOx emissions turn this type of hydrogen-powered ICE vehicle into a very attractive, very low-emission solution towards the transition to zero-emission heavy-duty vehicles.

MAJOR DEVELOPMENTS IN RETROFITTING AND CHASSIS MODIFICATION FOR H2 TRUCKS

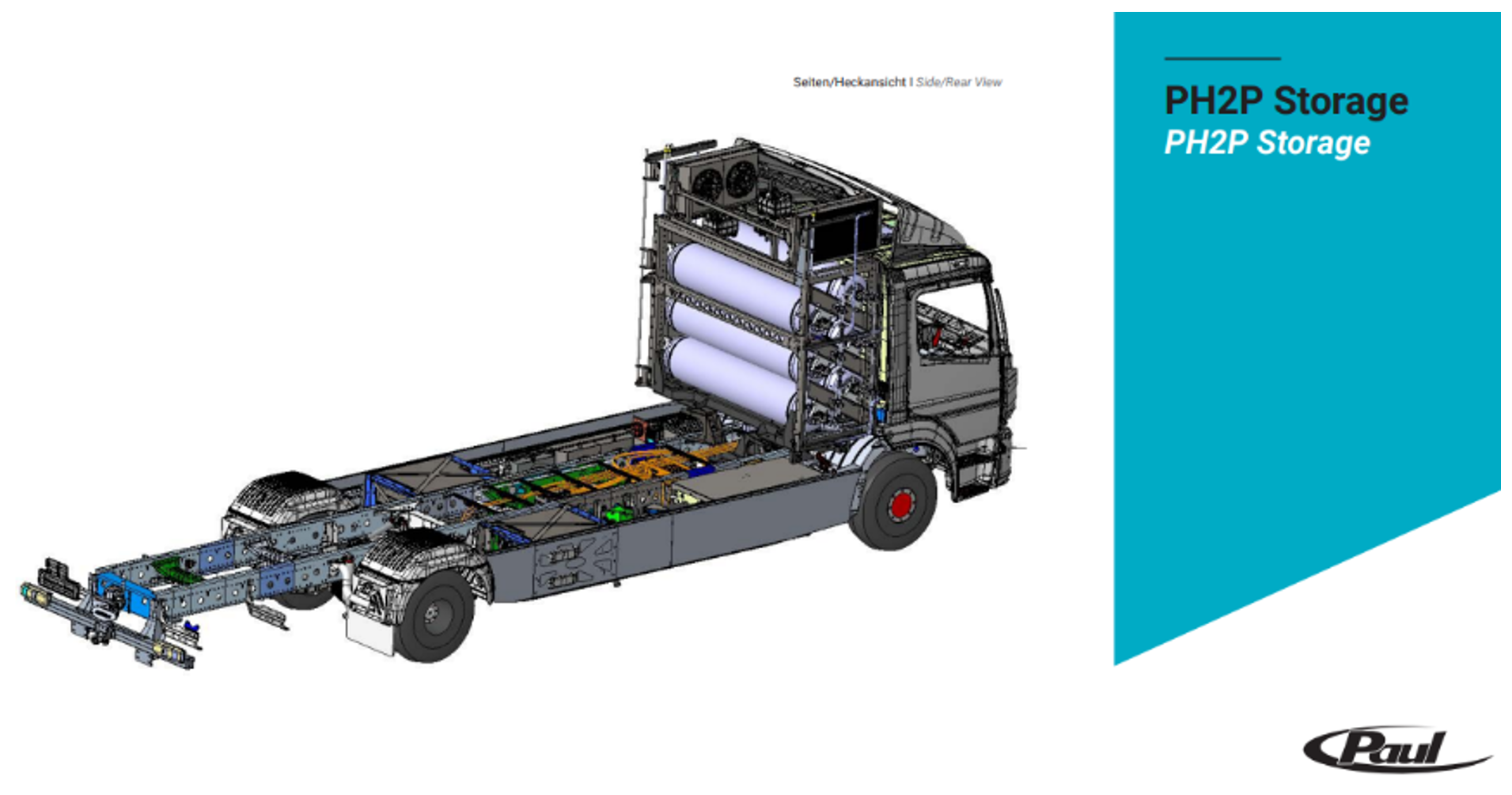

Paul Group

The Passau-based German group is a manufacturer of trucks, vans and buses based on mainly Mercedes chassis. Within the hydrogen sector, it unveiled its PH2P model built on a Mercedes Atego 4×2 Glider chassis at this year’s IAA Transportation in Hanover. Fitted with air suspension on the rear axle, the truck uses an 80 kW fuel cell from Toyota, along a 120 kW single-stage transmission from Voith with a continuous torque of 2800 Nm and two 60 kW batteries. The vehicle can be fully refuelled in 10 – 15 minutes.

The 6-tank PH2P Storage system can store 30 kilograms of hydrogen at 350 bar. Paul Group is a specialist in retrofitting chassis for solutions such as those required within the hydrogen sector.

Quantron

As part of the retrofit solutions for FCEV fuel cell-powered hydrogen trucks, the Augsburg-based German group Quantron unveiled the Q-Retrofit solution that is able to convert the powertrain of an existing diesel vehicle to a hydrogen-powered solution (see video).

Furthermore, Quantron published details of its own FCEV truck for the very first time. This vehicle was developed under a strategic joint venture with Ballard Power Systems and is fitted with an integrated electric axle from a leading powertrain manufacturer that provides a continuous power output of 400 kW. According to Quantron, the FCEV truck will be available in 4×2 and 6×2 axle configurations available from the second quarter of 2023. It is expected to have a range of up to 700 kilometres and will be able to offer a cockpit suitable for daily use in long-haul operations, says the German manufacturer. The FCEV truck will have over 50 kg of hydrogen tank capacity at 700 bar.

RANGE EXTENDERS

Tevva Hydrogen Electric Trucks

The British electric and hydrogen truck company unveiled its 19-tonne prototype (Class VIII) at this year’s IAA Transportation. Moreover, Tevva already owns an evolved 7.5 t hydrogen model, the TEV75BH2 (class V). The unveiled model is a breakthrough dual power system which combines lithium-ion batteries and a hydrogen fuel cell range extender. The truck range is expected to be up to 500 km based on the number of hydrogen cylinders (350 bar), which can be refuelled in 10 minutes.

The ultra-efficient REX dual energy system uses the FC fuel cell to support the dual battery electric motor, which ensures that the vehicle will only use hydrogen when required.

This means that:

- The fuel cell works as a range extender and does not directly power the engine.

- It can store a significant amount of energy in its batteries, so the truck can use that energy in less demanding work cycles.

MAIN TECHNOLOGICAL DEVELOPMENTS IN POWERTRAIN

Voith Group

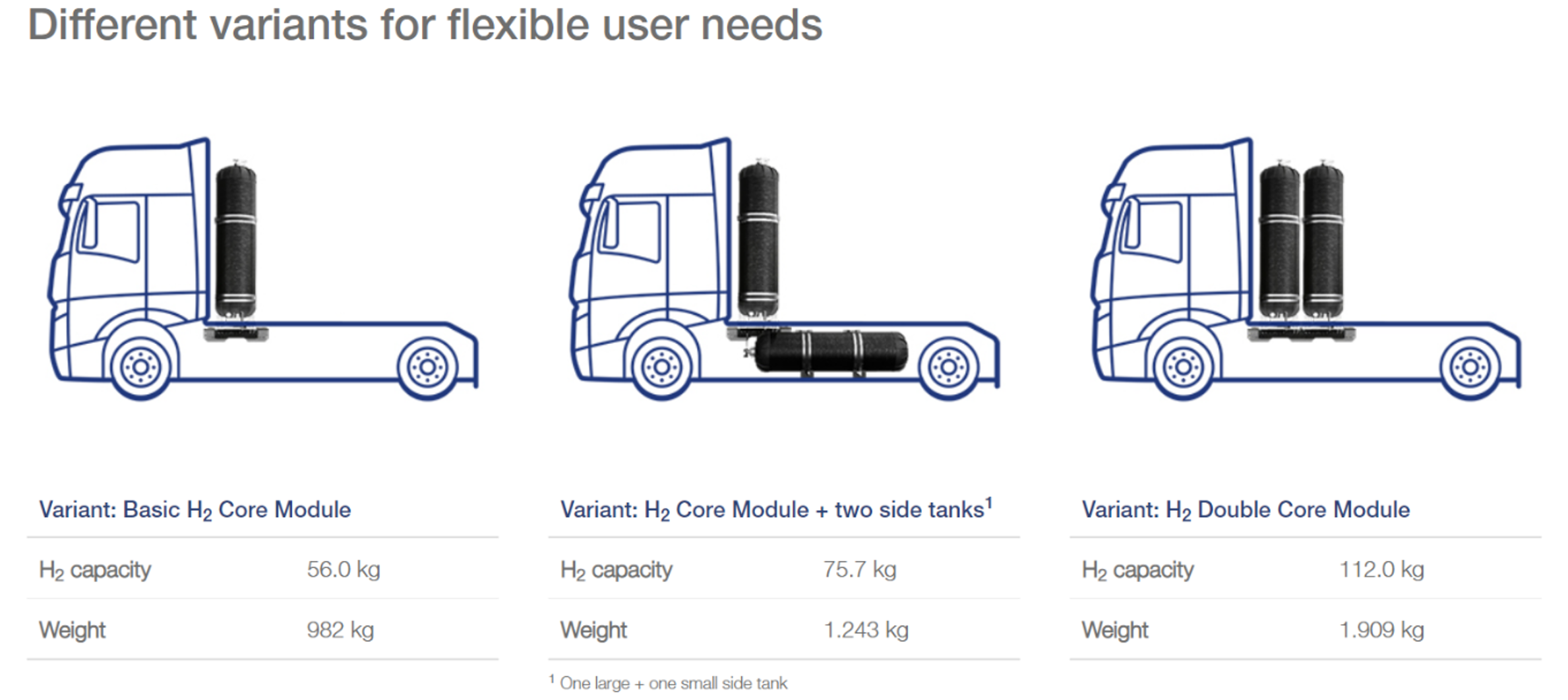

The Plug & Drive H2 Storage System with its own Type IV (700 bar) composite cylinders by the Munich-based technology group (see picture with its different versions) allows a range greater than 1,000 km and a low weight of the storage system. This allows additional payloads of up to 5 t versus equivalent BEV battery-powered trucks within the long-haul sector.

We were greatly surprised by the innovative design of the powertrain which is integrated in a single unit (electronic and manual valves, pressure regulator, check valve, filters, pressure and temperature transmitters) and its digital connectivity allowing exhaustive real-time monitoring of the refuelling conditions by means of an mobile phone application.

The Voith Group‘s large investment in R&D places the company at the leading position in all developments related to FCEV powertrain for heavy duty vehicles.

MADE IN SPAIN

The “Made in Spain” section of the exhibition at this year’s IAA Transportation was well represented by the digital vehicle diagnostics and predictive maintenance solutions developed by the multinational Cojali Group from Castilla-La Mancha.

Cojali attended the main trade fairs of the sector in Germany in 2022. The Castilian company unveiled its connectivity solution for fleet management using advanced remote diagnosis and predictive maintenance to optimise processes, keep the vehicle on track, avoid contingencies and lower costs. In addition, they also unveiled their advanced diagnosis solution. Both solutions are noteworthy for the competitive advantages they offer, for their “light and solid hardware, fully customisable, adaptable and intuitive software” and for their ability to develop tailor-made projects for vehicle manufacturers, all the way from the design to the testing stage.

Conclusions

The second summary article from the IAA Transportation in Hannover shows the diversification of solutions to achieve the long-awaited goal of zero emissions in heavy-duty transport drives the main manufacturers and stakeholders in the sector to explore multiple paths. According to previous articles, the commitment of long-range truck manufacturers towards the hydrogen sector is absolute.

Teaming up the major manufacturers with industrial companies that have extensive experience in the fuel cell technology leads to a win-win situation for the development and evolution of vehicles. The joint venture of Nikola-Bosch, Iveco-Hyundai, Daimler-Volvo, Renault-Plug Power, Quantron-Ballard Power, to mention but a few, ensures that the evolution, reliability and performance of their vehicles are increasingly enhanced, thus allowing hydrogen-powered trucks to be a true alternative for decarbonisation in the short and medium term.

We have analysed in-depth the spectacular innovations achieved in ICE hydrogen combustion engines, the range extender solutions being offered by some manufacturers, retrofit possibilities with fuel cell trucks, as well as new developments in digitalisation and components in the long range segment.

Under a scenario where low-tonnage electric trucks will coexist with heavier tonnage hydrogen-powered fuel cell electric trucks, the mobility sector is an essential offtaker for on-site renewable or green hydrogen production schemes in Europe, and especially in Spain, where 25% of CO2 emissions are due to road transport. The competitive price of renewable hydrogen production offers the Spanish market an attractive place for implementing hydrogen technologies, plus the additional advantage of not importing fossil fuels that emit pollutants.

SynerHy, powering net zero!