Hydrogen and heavy transport: IAA Transportation 2022 Hannover (Part One)

While the IAA Mobility Munich 2021 was the return at half speed of the most important event in the automotive sector after the pandemic, the IAA Transportation Hannover 2022 was the long-awaited comeback to normality within this sector. This time with a demonstration of the sector’s strength in heavy, last-mile and cargo transport. On both occasions, the SynerHy-Team had the pleasure of attending and enjoying the new developments in the industry.

Focusing on hydrogen, the IAA Mobility Munich 2021 was defined by the unveiling of the BMW i Hydrogen NEXT hydrogen-powered fuel cell electric model, whose mass production is due to start at the end of 2022. Whereas the hydrogen-related stands at the 2021 edition could be counted off the fingers of one hand, since the IAA Mobility is focused on passenger cars and commercial vehicles, this year’s edition of the IAA Transportation Hannover 2022 focused on heavy-duty and last-mile transport, which confirmed the key role that hydrogen will play in this area. The hydrogen sector, with its many stands spread across the eleven halls and two outdoor exhibition areas, exhibited an extraordinary level of strength and resources. Most manufacturers and associated industry have shown the latest innovations to be found in the forthcoming years within the hydrogen and heavy electric mobility sector.

On this first article, we would like to focus on the most important innovations available to truck and van that store hydrogen inside them both in compressed and liquid gaseous state. We will also review the many innovations that Bosch, the technology and service provider, is offering in its hydrogen mobility sector. In the next few articles, we will discuss the Spanish presence at the exhibition, heavy-duty vehicles powered by hydrogen combustion engines, innovations in retrofitting and the different components of the vehicles’ powertrain.

MAJOR INNOVATIONS FROM HEAVY-DUTY VEHICLE MANUFACTURERS

Nikola & IVECO

Undoubtedly, alongside the Bosch technology group, one of the most stunning stands at the event. Located in pavilion 24 and covering more than 400 m², its stand is a riot of digital and human resources, where a host of professionals and technicians explained the new developments provided by hydrogen technology to the heavy-duty road transport sector. The joint venture between the American start-up and the Italian industrial group unveiled the Nikola Tre FCEV beta version for this event, which is expected to be available during the first quarter of 2024 for the European market and during the last quarter of 2023 for the American market.

On a technical side, Nikola Tre’s range is expected to be more than 800 km, thanks to its ability to store compressed hydrogen at 700 bar. The Nikola Tre FCEV Artic 6×2 beta version boasts an auxiliary axle and a new cab to increase its aerodynamic performance. It can accommodate approximately 70 usable kilograms of hydrogen over a wheelbase of 3,932 mm and the refuelling time is expected to be under 20 minutes, with a peak power output of 480 kW / 645 hp (e-axle) and two 100 kW fuel cell stack modules (Bosch). As a curiosity, the Nikola Tre prototype displayed showed all the powertrain except for the placement of the storage tanks, which is the best-kept secret from a technical point of view (5 or 6 tanks). Remember that the tanks are placed at the rear of the cab and the sides of the chassis. The power generated by the fuel cell drives the electric motor and recharges the batteries that deliver the extra power required to achieve the 480 kW. In addition, the batteries store the energy generated by regenerative braking.

Figure 1. Nikola TRE FCEV 6×2 Model

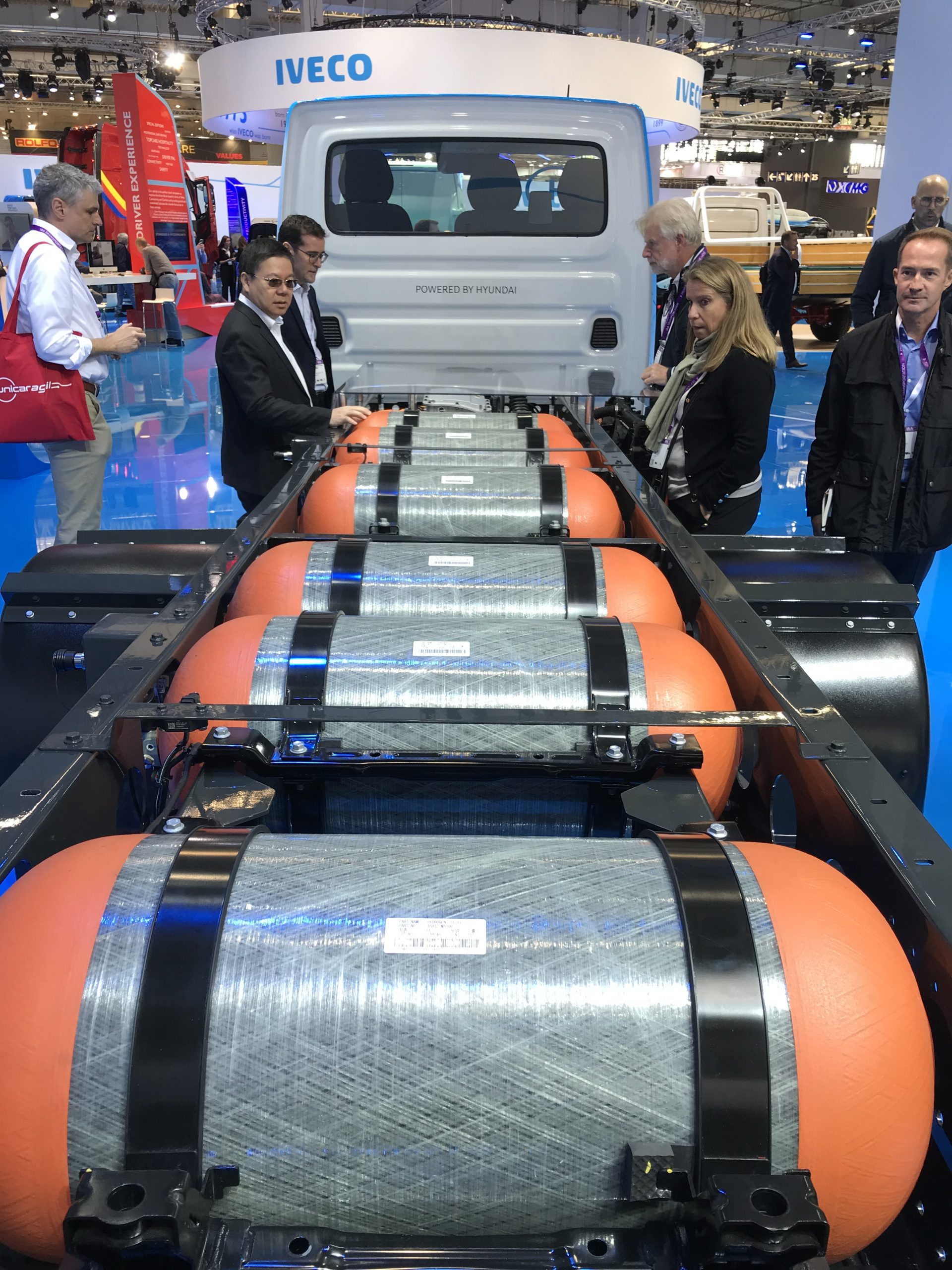

IVECO unveiled the prototype hydrogen version of its legendary last mile model for the van sector, the eDAILY Hydrogen model. It has a total power of 140 kW, a battery of 37 kWh and a storage system for 12 kg of hydrogen at 700 bar within 6 storage tanks. Its range is 350 km when driven in 90 kW FCEV fuel cell mode and an extra 50 km in battery mode. Hyundai provides the fuel cell technology for this model.

Figure 2. IVECO eDAILY HYDROGEN

IVECO offered the eDAILY Hydrogen for trial to those who were interested in testing it whilst fully loaded.

Renault & Plug Power (HYVIA)

HYVIA was born from the partnership between Renault Group, a leading manufacturer within the industry, and Plug Power, a global hydrogen solutions leader, combining their complementary expertise to contribute towards the decarbonisation of mobility.

HYVIA unveiled three models at this year’s event:

- MASTER VAN H2-TECH: With a 30 kW FC Plug Power fuel cell, 6.4 kg storage capacity in its 4 Type IV tanks at 700 bar pressure, a 57 kW / 76 PS electric motor and a 33 kWh battery. Its expected range is about 400 km, with an estimated recharge time of approximately 5 minutes.

- MASTER CHASSIS CAB H2-TECH: With a 30 kW FC Plug Power fuel cell, 4 kg storage capacity in its 2 Type IV tanks at 700 bar pressure, a 57 kW / 76 PS electric motor and a 33 kWh battery. Its range is approximately 350 km and it only takes about 5 minutes to recharge. The main difference with the VAN H2-TECH is the layout of the tanks and the fuel cell (see video below).

- MASTER CITY BUS H2-TECH: The HYVIA group’s big new vehicle. This prototype can accommodate 15 passengers, with an FC Plug Power 30 kW fuel cell, a storage capacity of 4.7 kg in one Type IV tank at 350 bar pressure, an electric motor of 57 kW / 76 PS and also a 33 kWh battery. The estimated range is about 300 km and a recharge time of less than five minutes. Storing at 350 bar and not at 700 bar might be explained by the fact that it is in accordance with other manufacturers of 12 and 18 m city buses, such as Caetano (Toyota), Solaris (CAF) or the Belgian Van Hool group.

Here below, there are some photos of the event and a video where all three models can be appreciated in their conceptual design:

Figure 3. Master Van H2-Tech

Figure 4. Master Chassis Cab H2-Tech

Figure 5. Master City Bus H2-Tech

Hyzon

This American company with its headquarters in Rochester (N.Y.) has a wide range of light- and heavy-duty hydrogen trucks. There are light-medium trucks ranging from 6-20 tons (40-80 kW battery power) and heavy trucks ranging from 40-70 tons (100-150-200-370 kW) and both three and four axles. The image below shows a prototype of a truck with the “European” cab from Hyzon’s assembly site in Europe, more precisely in Groningen (The Netherlands).

The HYZON HYMAX-500 model has a 500 kW peak electric motor and a 150 kWh battery. It is powered by a 200 kW fuel cell from the Singapore-based manufacturer Horizon. It can store 45 kg of hydrogen compressed at 350 bar, and it has an estimated refuelling time around 15 minutes and a mileage range of almost 400 km. The American group recently signed a contract to supply 150 trucks to DB Schenker, the German multinational logistics company.

Figure 6. Hyzon HYMAX-500

Daimler Truck

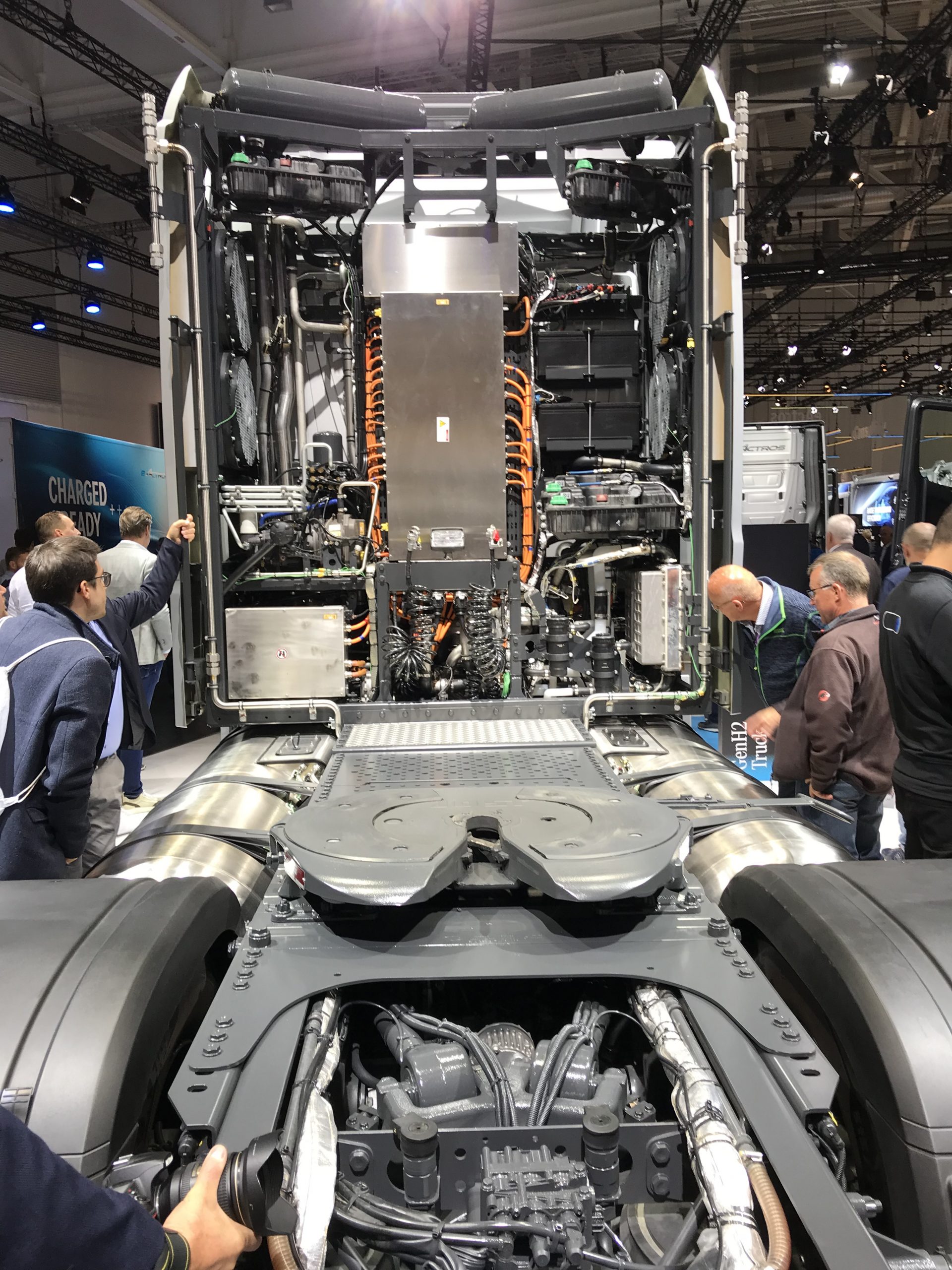

Along the path to the zero-emission transport of the future, first fuel cell prototypes of the Mercedes-Benz GenH2 Truck have been intensively tested since last year, both on in-house test tracks and in authorised tests on German roads. The Stuttgart-based German transport company committed from the very beginning to trucks equipped with liquid hydrogen storage at -253 °C stored within two cryogenic tanks at the front on either side of the chassis that can store 80 kilograms, thus proving the feasibility of a hydrogen-powered electric fuel cell truck with a fully load weight of more than 40 tonnes. The Mercedes-Benz GenH2 prototype currently tested on the road is refuelled with gaseous hydrogen (see video below). However, another GenH2 prototype truck with liquid hydrogen tanks has also been displayed at the Mercedes-Benz Trucks stand at Hall 19/20 for the IAA Transportation 2022 in Hanover (see image below).

The focus here is set on the liquid hydrogen-based prototype, the German group’s big stake in the mid to long term. Hydrogen in its liquid state has a significantly higher energy density relative to volume than gaseous hydrogen, thereby being a major energy carrier in this state.

This allows more hydrogen in two tanks (80 kg for the evolved prototype unveiled in Hannover), which significantly increases the range (up to 1,000 km), thereby enabling the vehicle to achieve a performance similar to a conventional diesel truck. As a result, the truck is perfectly adapted to highly challenging operations, in particular within the crucial long-distance heavy transport sector. The exhibited prototype (19 tonnes) has a payload similar to a diesel truck in the corresponding range (25 tonnes), powered by an electric motor with a peak power output of 660 kW (2*230 kW). Two 150 kW fuel cells are supplied by the joint venture CELLCENTRIC between Volvo Truck & Daimler Truck. In addition, there is a 70 kWh battery system capable of a temporal power output of up to 400 kW.

Figure 7. Liquid H2 Mercedes Benz GenH2 Truck

Figure 8. Compressed H2 Mercedes Benz GenH2 Truck – FAURECIA

The configuration of the prototype’s powertrain is diametrically opposite to the compressed hydrogen models. Fuel cells are installed under the cockpit, allowing the front radiator for cooling purposes as well. Not placing storage tanks at the rear of the cockpit keeps the dimensions of it, crucial for long-haul trucks, as well as fitting the low and high-power DC/DC converters. The chassis holds the battery system and the electric motor. Hence, the small size of the two LH2 storage tanks allows a far more efficient layout in technical terms than the 350 or 700 bar compressed hydrogen truck models.

Beside the hydrogen storage tanks of the GenH2 model from the Austrian manufacturer SAG Austria GmbH (model LH2 Poseidon), there were also models manufactured by the French manufacturer Faurecia (under its Forvia brand in collaboration with Air Liquide) and the Canadian manufacturer Magna International, this time with 45 kg H2 (see picture).

Figure 9. Liquid hydrogen tank model – Magna International

Figure 10. Liquid hydrogen tank model – Faurecia

The start of mass production of the GenH2 Truck is expected within the second half of the decade. Daimler Truck allowed visitors of the IAA Transportation in Hanover for a tour of the liquid hydrogen-powered truck.

KEY DEVELOPMENTS FROM THE MANUFACTURERS OF TECHNOLOGY AND COMPONENT SUPPLIERS

Bosch Group

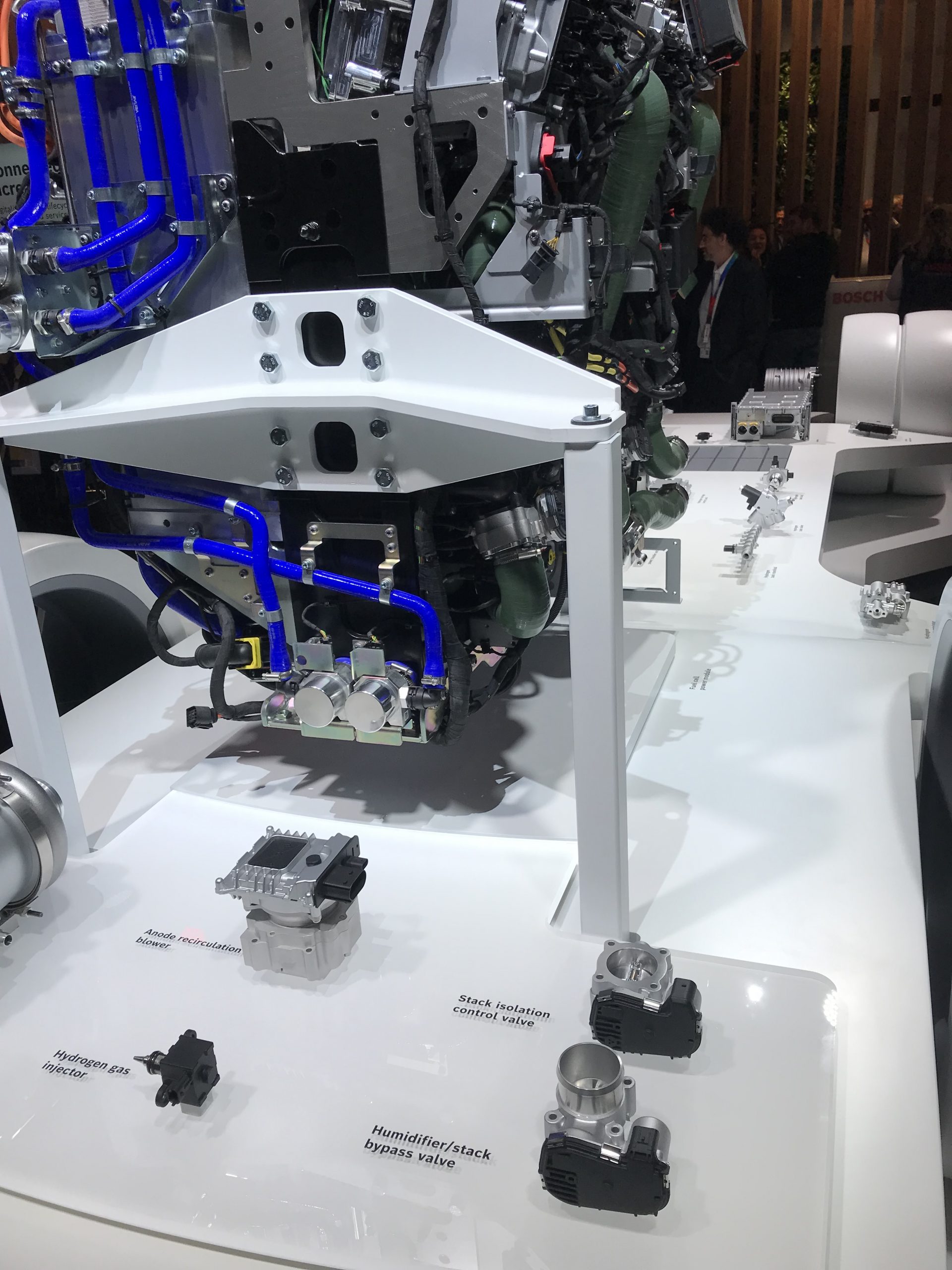

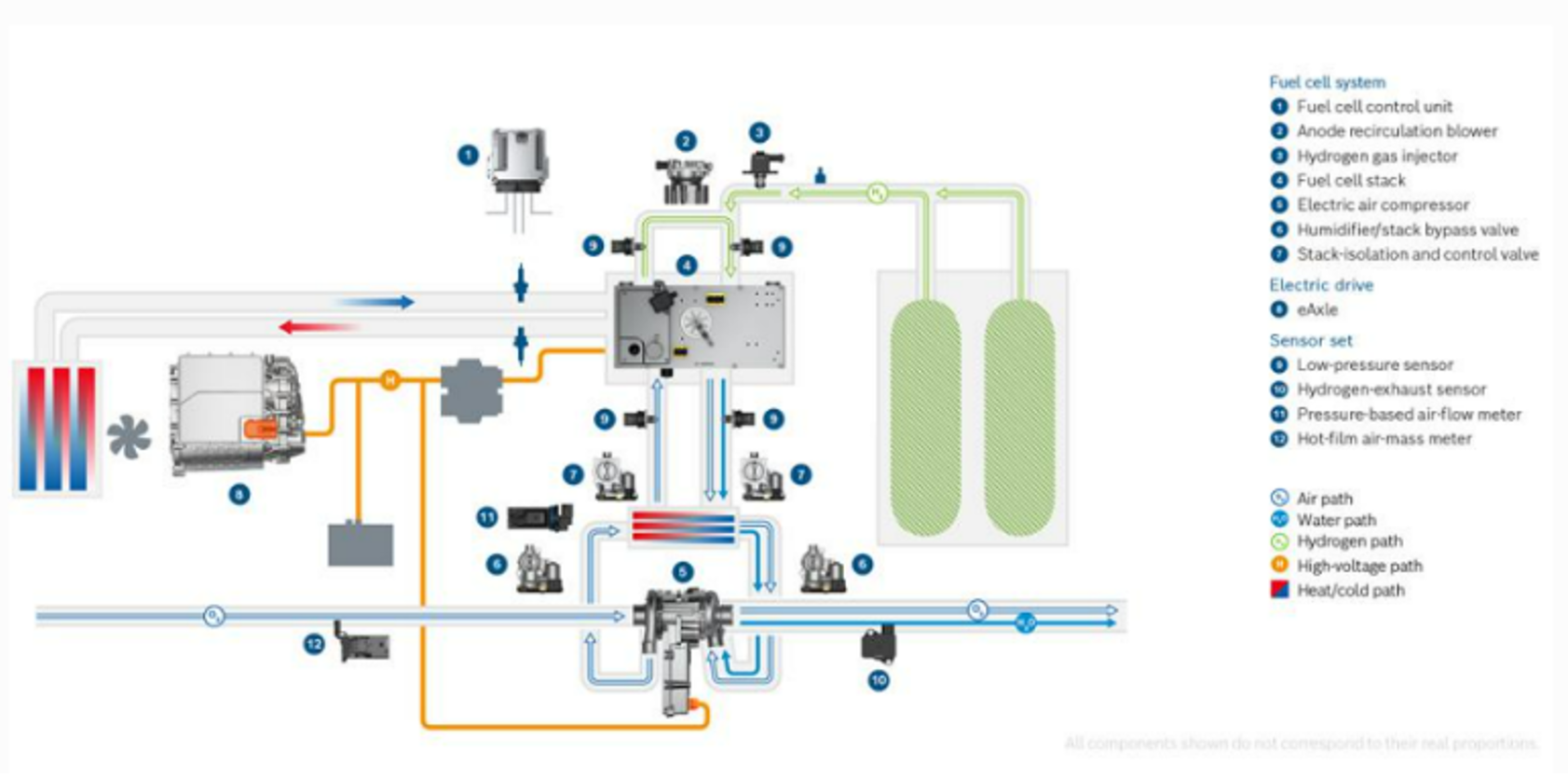

An overwhelming portfolio of products exhibited by the Baden-Württemberg-based technology group this year at the IAA Transportation in Hanover. The group’s hydrogen strategy and its commitment in this area is complete. A very extensive list of exhibited components could be seen on exhibit:

- Fuel cell stack, anode recirculation blower, gas injectors into the FC, stack isolation control valves, bypass humidification valve, electric mini air compressor, air-mass meter.

- High and low voltage DC/DC converter, battery electric current sensor, electric engine, hydrogen storage control unit, sensors for hydrogen level concentration, electric engine.

- On tank valves OTV, pressure regulators, hydrogen distribution valves.

The Bosch technology group has been deeply engaged with the development and evolution of hydrogen fuel cell systems for mobility recently, besides the electric powertrains used on several of Nikola’s long-haul trucks. The German company manufactures electric motors but also offers a range of electric powertrain units with integrated gearboxes and power electronics intended for commercial vehicles.

The expected investment in fuel cells raises the total investment to over a billion euros by 2024. Besides developing FC, Bosch is also broadening its efforts to manufacture other core components and electrification technology.

Conclusions

To sum up this first summary article of the IAA Transportation in Hanover, the commitment of the long-range truck manufacturers in the hydrogen sector is absolute. Except for the Scania Group, all other manufacturers have exhibited their prototypes based on the hydrogen technology. MAN also announced prototypes for 2023.

Teaming up the major manufacturers with industrial companies that have extensive experience in the fuel cell technology leads to a win-win situation for the development and evolution of vehicles. The joint venture of Nikola-Bosch, Iveco-Hyundai, Daimler-Volvo, Renault-Plug Power, Quantron-Ballard Power, to mention but a few, ensures that the evolution, reliability and performance of their vehicles are increasingly enhanced, thus allowing hydrogen-powered trucks to be a true alternative for decarbonisation in the short and medium term.

The investment of technology groups such as Bosch, Faurecia and Mahle ensures a high quality in terms of vehicle performance, electronics and digitalisation, exponentially enhancing the customer experience for the users of this mobility target area. Within a scenario where low-tonnage electric trucks will coexist with higher tonnage hydrogen-powered fuel cell electric trucks, the mobility sector is an essential offtaker for on-site renewable or green hydrogen production schemes in Europe and particularly in Spain, where 25% of CO2 emissions derive from transport. The renewable hydrogen production at a very competitive price turns the Spanish market into a hotspot to implement hydrogen technologies, plus the benefit of avoiding the import of fossil fuels responsible for particle and pollutant gas emissions.

In upcoming blog posts, we will review the outstanding developments in hydrogen combustion engines, the range extender solutions offered by some manufacturers within the sector, the retrofit possibilities for fuel cell trucks and new developments in digitalisation and long-range components.

Stay tuned!