The relevance of control software in the hydrogen field

A power management system (PMS) is the system that provides detailed information about the energy flow in a generation facility.

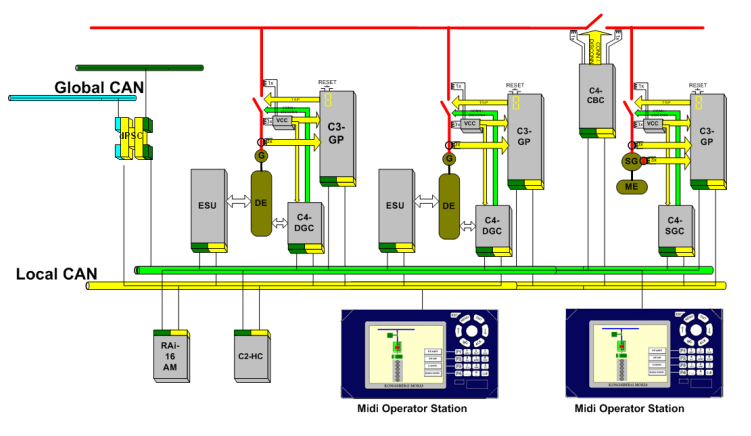

Figure 1. Typical PMS configuration including protection of the generator

A PMS system can be applied to any type of power generation system, although here we focus on 100% renewable energy generation systems, from PV to renewable hydrogen generation and its different security and control devices. This system must help to digitalize, secure, monitoring and automatizing the production of electricity and renewable hydrogen.

We talk about a platform for data acquisition and analysis of Asset Management, aiming to achieve a set of objectives during its development:

- Design and deploy a service-oriented software architecture (SOA).

- Design and deploy a hardware architecture that ensures the scalability of the solution and is suitable according to the SOA architecture.

- Develop the functionalities which allow the management of the data of the facility. To achieve such a goal:

Implement tools to acquire and integrate all data in a centralized database.

Store the log of data/signals generated by the assets.

Provide decentralized access to real-time and/or historical data.

Process data in a secure and efficient way.

Create basic reports from the stored data.

- Develop functionalities to manage the information of the facility. For this purpose, the system must be able to:

Generate reports from stored data either from the assets or from other systems attached to the system platform.

Perform analysis of technical and operational data or other variables.

Improve the performance and efficiency of the assets installed.

- Develop modules and functionalities to digitalize and monitor hydrogen use and balanced consumption on real-time, based on Artificial Intelligence and Machine Learning technologies.

- Digitalize and secure the generation of electricity and hydrogen from the facility through blockchain for its use in sustainable mobility.

- Guarantee the interoperability of the solution and its scalability to other facilities generating electricity and 100% renewable hydrogen that can be used to recharge zero-emission vehicles.

The main goal of a PMS system consists of a measurement platform and a Data Acquisition system that will noticeably improve the overall measurement process of the facility, by integrating each of the modules defined. This end goal must be achieved by means of IoT technologies, Big Data and Artificial Intelligence techniques (Machine Learning), implementing existing methodologies already used in Industry 4.0.

Specifically for renewable hydrogen, a PMS system must be able to at least display the following information:

- Electrolyser production level, flow rate per time measurement.

- Storage level in the tanks and HRS zone.

- Sensor information of the facility.

- For HRS analysis, number of refuelling per time measurement, including H2 consumption in each refuelling.

How can a PMS software be developed?

First of all, the functional description of the solution needed to develop the PMS system must be clarified. For a renewable hydrogen production and consumption infrastructure, each module of the facility will generate a large amount of data on a daily basis, some of which will be stored in specific databases and storage systems and some of which will not be logged in any long-term data persistence system and thus cannot be analysed or queried afterwards. Furthermore, some will be centralised on servers, hampering access to similar information from different locations.

This scattering can lead to duplicate master data, causing outdated information between systems and applications. Consequently, there is a lack of data integration between related information, hindering an overall view of the facility’s asset status, which is especially relevant for a generation plant aimed at quickly and reliably refuelling vehicles as an HRS facility.

Implementing a platform to centralise all data, generate reports and analyse assets will require integrating this platform with the other applications and systems.

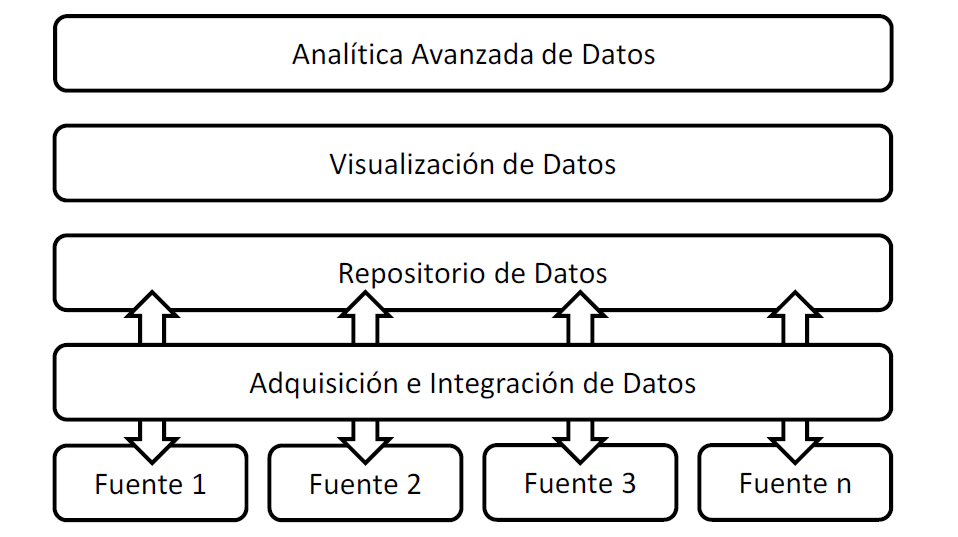

Figure 2. Overall functioning diagram of a PMS system

For easy development of new functionalities on the PMS platform, it is recommended to use a standard architecture, which would allow the development of new modules and the integration of new applications and their requirements.

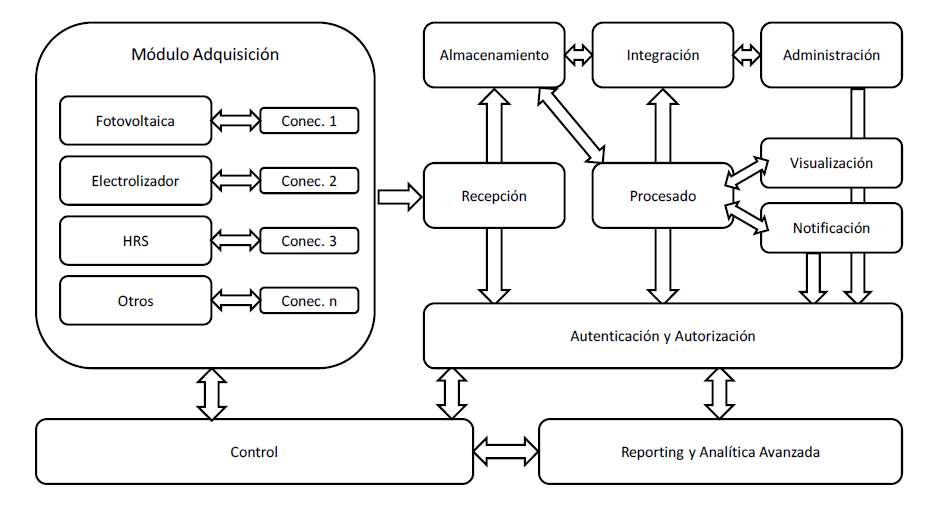

A PMS system adapted to the production and consumption of renewable hydrogen in a HRS, energised by a photovoltaic facility, can be designed using a modular architecture such as the following:

Figure 3. Modules in a PMS system

Upon the deployment of a PMS system, the necessary capacity to effectively control the renewable energy and hydrogen produced will be developed, thereby automatizing the operational processes required to correctly satisfy the energy demand at every single moment.

Such a tool enables the analysis of the data generated by each element of a renewable hydrogen production infrastructure, but also, develop the necessary links for each of the safety and control systems to integrate all the safety features of the facility.

Another benefit of a PMS system is to certify the renewable origin guarantee, both for the energy and for the hydrogen generated in the electrolyser, by using blockchain securitisation.

Finally, by means of machine learning techniques, a hydrogen production system with HRS will be able to foresee future consumption of both energy and hydrogen, based on a continuous analysis and learning of the current levels of consumption, helping to provide new dimensions to fit the new needs of current and future customers.

REFERENCES